Harbor’s Wharfingers and Cargo Marketing teams are making progress on easing the crunch.

Harbor’s Wharfingers and Cargo Marketing teams are making progress on easing the crunch.

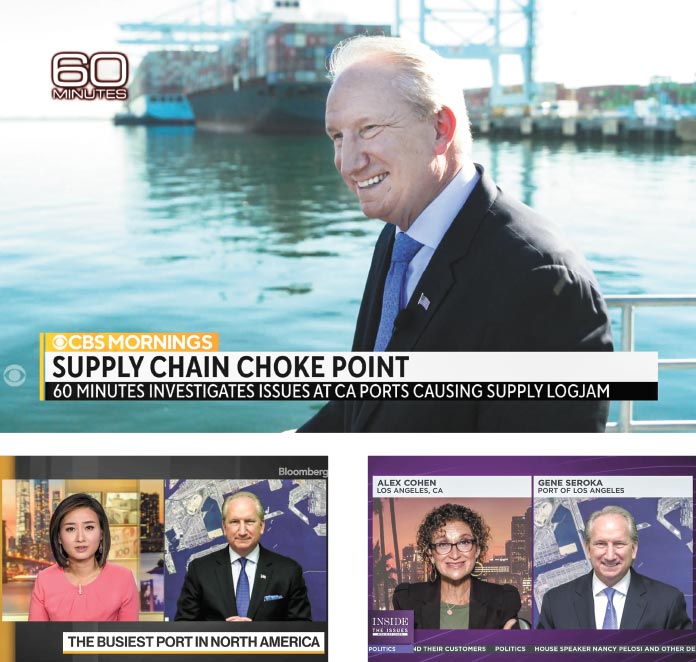

Late last year, as the supply chain surged in record freight tonnage and ships backed up trying to get into the Port, Executive Director Gene Seroka was on television and in the papers more than just about anybody. He was busy explaining what was going on.

Behind the scenes and under enormous pressure and scrutiny, the Port’s Wharfingers – possibly its oldest job title – and the team from Cargo Marketing were working long hours remotely and ramping up their capabilities to ease the crunch.

Progress was palpable. The supply chain crisis is not yet over, as Gene Seroka told the LA Times in early January. “No one is taking a victory lap,” he told the paper. “No one is high-fiving each other.” But progress was made in many critical data metrics. The number of ships waiting to dock has stabilized. The number of loaded import containers sitting on the docks has decreased by more than 50 percent (aided by a new container dwell fee not yet imposed on the shipping lines). And there is a big push to reduce empty containers on the docks. Data modeling from the Port helped shipping companies to prepare for what was coming and to distribute what had already arrived. It was an all-hands-on-deck effort to ease the crunch.

In this feature story, read about the efforts – still ongoing – made by the Port’s Wharfingers and the heavy data management from Cargo Marketing to help clear the decks.

The Club thanks Harbor’s Rachel Campbell for her assistance.

The Port in the News

Port Executive Director Gene Seroka was almost omnipresent on national and international media during the supply chain crunch last fall. Some of his appearances:

CBS/60 Minutes

Fox 11 LA

Bloomberg

CNBC

Yahoo News

Spectrum 1 News

The Wharfingers

The Wharfingers

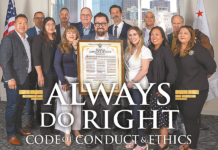

Like most City personnel during the pandemic, the Port’s Wharfingers have been working remotely. Here are some of them:

(Some photos were taken pre-pandemic.)

Cargo Marketing

The Cargo Marketing Division activities include the promoting and use of the Port’s digital cargo visibility tool, the Port Optimizer, which helps supply chain stakeholders in the planning of their freight several weeks ahead of the event. Like most City employees during the pandemic, they are working remotely. (Some photos were taken pre-pandemic.)

‘It’s Been Very Busy’

‘It’s Been Very Busy’

On Dec. 10, Club CEO Robert Larios andeditor John Burnes interviewed Damien Young, Chief Management Analyst and Director of Wharfinger Operations, via Zoom due to pandemic protocols. Damien has 23 years of City service.

Alive!: Damien, thank you for giving your time to our readers today.

Damien Young: Sure.

It’s been a heck of an eight or nine months for the Port and the Wharfingers. But before we get to the supply chain, tell us what path you took to get to your current position.

Damien: I tell people I’ve moved about 12 feet in 28 years because I started as a student worker in the Wharfinger division back in 1993. That was my first taste of the City a long, long time ago now, and time goes very fast. I had a great time and learned all about the City, and then I came back a few years later full time with the City at Aging, Building and Safety, Public Works, Water and Power, LAWA and back to Harbor. I can’t hold a job I guess!

How long have you been back at the Harbor?

Damien: Since 2007, so about 14 years now.

About Damien Young

Damien Young is the Director of Wharfinger Operations for the Port of Los Angeles, the nation’s leading container port and economic generator. Wharfinger (pronounced war-fin-jer) is an industry term for the keeper or owner of a wharf, similar to a harbormaster. The Wharfinger team at the Port of Los Angeles is responsible for the day-to-day activities at cargo terminals and serve as agents for Port customers. Young manages the billing of more than $400 million in annual shipping service fees, including wharfage, dockage and pilotage, as well as space assignment charges, commercial fishing charges and film permit fees. He estimates, plans and reports on shipping container and other commodity volume statistics and trends, and works closely with senior management and the Port’s Cargo Marketing and Media Relations divisions on forecasting container volume levels. Young joined the Port in 2007 as the Manager of Administration for the Port’s Construction and Maintenance Division, where he oversaw budget, contracts, payroll and accounts payable and managed $5 million in capital projects. He then served as Assistant Director in the Port’s Contracts and Purchasing Division until joining Wharfingers in 2017. Before joining the Port, Young worked in several other City of Los Angeles departments, including Aging, Building and Safety, Public Works, the LADWP, and Los Angeles World Airports. Young has a bachelor’s degree in political science from UCLA and master’s degree in public administration from Cal State, Long Beach. |

Supply Chain Status Check

For at least a month now [the interview was conducted in early December – Ed.] we’ve been hearing on the national news about supply chain constraints before the holidays. Can you give us a status check on where things are generally? Are things alleviating a little bit?

Damien: As a port we’ve been very busy obviously, and the volumes are still at record high levels. They’ve been that way since July of last year, so we’ve had about 16 or 17 months like that. We’ve averaged about 900,000 of what are called TEUs, which are 20-foot equivalent units – the industry version of a container, basically. It has not stopped for a long time. I’m reporting numbers this month that are a touch lower than last year, so we might finally be seeing a bit of a slowing there. But it’s been very hectic and very busy for that period of time.

Basically what happened was this: The pandemic started, and in Asia and China the factories all shut down. It was very quiet here, we had almost no business for a couple of months. And then as the country was trying to reopen, the people in the United States started ordering everything. The factories reopened in China and then the surge started at that point, and it has been going gangbusters ever since.

And there was a really big surge once the factories started opening up. When that happened it really hit hard because …

Damien: People here were locked down. They were ordering things, and that’s when that whole thing started. Our Executive Director Gene Seroka has been going over this a lot with the media for the last few months.

Absolutely. We’ve seen it.

Damien: Right.

Wharfingers

The Port’s Wharfingers [pronounced WHARF-injers] have played a huge role in the management of the supply chain surge. Can you give us a basic definition of a wharfinger?

Damien: Well, a wharfinger does a lot of things, especially these days. Each freight company has a different Port terminal where their ships come in and out. Each Wharfinger is assigned a terminal, and they process all the billing for that terminal. It could be a container terminal, where you see all the containers coming in, or a cruise terminal, a fruit terminal, an auto terminal, a steel terminal … we have different oil terminals, a scrap metal terminal and then commercial fishing slips. We are assigned to all of those parts of the Port, and we handle the billing.

But it’s more than just billing. We also act as liaisons to that terminal, and we work with the operations folks to ensure that the infrastructure is repaired and maintained. We work with C&M, our construction and maintenance group, and engineering to make that happen. The only difference today is that we used to go out to the terminals on a regular basis, but with people working from home and COVID protocols, it’s a more telephonic- or email-based connection with the terminals.

We also process a lot of film permits for productions that want to film here at the Port. It’s been very busy; we process about 10 to 20 permits a month.

We read water and electric meters to bill back tenants. We handle layberths – vessels that dock at the Port on a onetime basis for repairs or special events like Fleet Week ships. We process space assignments to tenants so they can find extra space in supplemental areas for their chassis or containers, especially right now. I address a lot of CPRA requests with community and media relations, and we implement tariff changes.

It’s a busy operation, but that’s basically what we do.

Basically that’s tons of responsibilities.

Damien: You see a lot of what’s going on at those terminals, how operations are going, and how volumes are increasing or decreasing.

Are the Wharfingers responsible for predicting problems or issues or bottlenecks?

Damien: One of my jobs is to forecast volumes going forward in the short- to intermediate-term. Historically we’d use actual data to do that, and I gauge how many ships are going to come during certain periods of time and monthly estimates. I talk to senior managers about what we see on the horizon, literally and figuratively. We have a tool called the Port Optimizer that we use to help educate us on how we can see what those numbers are going to be going forward. It’s not always 100 percent accurate because it’s a tough business to guess on, but we have container data that helps inform us about that.

Are Wharfingers sort of independent to see and solve any problems on their own, or is it pretty structured?

Damien: It’s less structured than other positions in that we’re kind of an independent operator – you go out to a terminal, you’re driving around, you’re avoiding getting hit by trucks and you’re making sure what’s going on. You talk to the operations folks and say, “Hey, this light pole is out. This electrical vault needs to be fixed.” We report back the C&M to get that fixed.

Tons of responsibility, it sounds like.

Damien: It can be. It’s a lot of multitasking, that’s for sure.

How long have Wharfingers been around?

Damien: A long, long time. It’s probably one of the oldest positions here at the Port. Back in the early, early days, you went down to the docks and counted the tons that were coming in. Today it’s high tech and automated to a point where we do less on the ground than we used to. But we still have to interact and deal with all of the people at the terminals. It’s a mix of the old and the new. With all that we’ve done with this pandemic, we couldn’t have done this 30 years ago. We can continue our operations wherever we are in the world. We can get things done.

How many Wharfingers and support staff do you have?

Damien: We have ten Wharfingers between twos and ones. We have three clerical positions; only one is filled right now because two of our clerical were promoted to Wharfingers very recently. I have a Management Analyst, and we have two student worker positions, and then myself. It’s not an enormous group, and we’re very busy.

‘We’ve gone from under the radar to right in front of everybody’s screen every night.’ — Damien Young

In the Middle of It

The Port has been in the news all around the world in the last six months. Are Wharfingers right in the middle of it?

Damien: You could say that. We’re the ones who receive all the reports of the container levels for all these ships, so we know how full they are. I take that data and distill it and create reports for management so they’re aware of what’s going on. A lot of the source data that Gene Seroka and the other managers use comes from my operation; a lot of it is Wharfinger data that we provide, and they use that for ship counts and volume counts and things like that. We’re not on the screen, but we’re providing all of the information for those people who are.

What’s your firsthand observation of the backlog? Is it easing up?

Damien: The Port passed the tariff change to establish a fee to charge a shipping line if they don’t remove a loaded container once it gets off a ship. The Port postponed it because the threat of the fee has forced action, and now we’ve seen about a 50 percent reduction in the number of these containers that have been sitting there for more than nine days, which is the cutoff they used. [The fee delay is continuing at press time. –Ed.]

Fifty percent – that’s huge.

Damien: We haven’t collected a dollar yet, but the companies have been moving those containers, which is great. I think we’ll probably delay that fee until a certain point, but it’s up to Gene and the managers. We’ve seen some great progress on that front.

That was the goal.

Damien: Clearing those containers allows more space on the dock. When ships come in, we can work those faster and move things. The fluidity levels can increase and then you have more ships coming in, fewer waiting at anchor, and the whole chain works that way – you can get them in faster, so it would alleviate those problems. Little things like that mean big changes.

How are the Wharfingers contributing to this easing of the backlog? Is that part of their responsibility?

Damien: The Wharfingers process space assignments which help to free up necessary space for container terminals. We have issued about 50 space assignments so far this year, which is far more than usual. It’s to establish space for containers and truck chassis and move them off the terminals. My group works with [Port] real estate on that. It’s been a constant this year.

My group processed $400 million worth of invoices in the last fiscal year ending June 30th. It’s record volumes, record revenues. It’s been very busy.

Talk about the signs of success that you’re slowly clearing the backlog.

Damien: Sure. I mentioned the 50 percent reduction in the loaded containers on dock for more than nine days; that’s a huge help. It keeps things moving. The wait time for rail is down to about two days where it was a 13-day delay a few months ago. The delays are coming down. We still have a lot of ships coming in – a few fewer than we had at the peak, but that will help alleviate that problem. We’ve had ships here that have come to berth, and sometimes they just sit there because there’s no space to put containers on those docks and it kind of jams up the system; when they don’t pick up the containers or the warehouses are too full, it blocks the system from working. The shipping lines have reduced those volumes; that helps the ships come in, get worked and so that help things move faster. And the reduction of empty containers at the terminals is a big help, too.

Media Glare

How does it feel to have the world looking upon you? Have you ever been in that position?

Damien: It’s kind of remarkable, I was watching the news with my kids the other day and Gene came up and I said, “Oh yeah, there’s Gene again.” My kids are almost used to it now. Gene met with President Biden a few months ago and he has many weekly meetings with the White House staff on how they’re looking at things. Gene was on 60 Minutes. It’s remarkable, but it’s good and bad. It’s good because we’re showing how much we actually do. A lot of stories are negative, but people miss the fact that we’re processing more than ten million container units a year at this rate, almost 11 million. That’s a lot of freight; that’s more than we’ve ever done by a factor of about 13 percent. So yes the eyes are on us. Maybe it makes us work better, work faster and work smarter.

How stressful have your days been? Are you getting any sleep?

Damien: I don’t get sleep because I have a two-year-old; that’s a different story. It’s stressful, but I think it’s a good stress. We’re working very hard to fix the problem, to get things moving and keep things going. The managers are feeling the same way. It’s a lot of work, but we’re glad to see it happening.

The Cargo Crew

Talk about the professionalism and dedication of your team.

Damien: They’ve been great. They’ve been very busy and they’ve been doing it all from home – $400 million of invoicing was all done on their computers at home because we’ve been out of the office since March of 2020. It’s been a lot of emails and a lot of communication that way, but it’s managed to get done and they’ve done it well. One of our goals is good customer service, and we’ve continued that. I couldn’t be more proud of them. They’re a fantastic group.

What do you wish people knew about what your department does?

Damien: We’ve been around for 114 years now, and I think everyone knows what we do now! I’m not worried about people wondering what the Port of LA does anymore; I think people know us more than LAWA now even at this point. We’ve gone from under the radar to right in front of everybody’s screen every night.

A Passion

What do you love about what you do? To be operating at such high level, you must have a passion for what you do.

Damien: I’ve always been a numbers guy, so this is the ultimate numbers game. We have numbers of containers and ships and tonnage of steel. Last year my son was learning about counting collections at school and I said, “That’s what I do, we count collections of things at the Port. So do well in math and you’ll be just like your papa, you can come and work here.” It’s a lot of numbers, and I’ve always been strong in numbers. This is right up my alley.

Did you train to be a numbers guy?

Damien: No, of course, no, why would I do that! No, I was a political science major at UCLA and I came to the City and worked up the analyst ladder basically from a Management Assistant all the way to chief MA. You learn so many things at every level and at every department. I’m so glad I’ve worked at all the departments I worked at because you gain so much knowledge. It’s been a great path and I recommend it to anybody. If you move around a little bit, learn new things and meet new people, it’s a good path even if you come back to where you started like I did.

Thank you so much for your time and for all you’re doing for the Port and the City of LA.

Damien: Thank you. We’re trying, we’re trying.

‘Optimizing the Data’

‘Optimizing the Data’

On Jan. 11, Club CEO Robert Larios and Alive! editor John Burnes interviewed Eric Caris, Director of Marketing, 20 years of City service, and Melissa Knight, Management Aide, 18 years, both of the Cargo Marketing Division. The division manages cargo data, which plays a critical role in predicting and handling the cargo on its way to the Port of LA, and within it. The interview took place via Zoom due to pandemic protocols.

Alive!: Thank you, Eric and Melissa, for explaining the data side of managing the supply chain at the Port of LA. First, Eric, can you tell us a little about your career upto this point?

Eric Caris: My career started in 1982 in Europe working for a shipping line. As you can probably detect from my accent, I was born and raised in Belgium in the port city of Antwerp. In a roundabout way, I landed in California a couple of years later working for a subsidiary of that same shipping line in their Long Beach office. We handled both break-bulk and containerized cargo. I became regional director for the California region, a position I held for about 13 years. An opportunity presented itself here at the Port of Los Angeles in the Marketing Division and was hired on an emergency appointment basis. Prior to being hired, I was active within the industry. I served on the board of the Steamship Association of Southern California and as a result had many connections with other shipping lines and marine terminal operators. I joined as Assistant Director of Marketing and remained in that position until about five years ago when I was promoted to Director of Marketing.

When I joined the Port there were many more shipping lines compared to today. We had about 30 decent size container shipping lines calling at this Port complex. Today, through mergers and acquisitions, that number has come down to 10 major global shipping lines, and some smaller independent operators. Our day-to-day activity is really on the sales end of things. The Marketing Division at the Port is best compared to the sales department within an organization. We are always in front of importers, shipping lines, the marine terminals, and other ports within the United States, and around the globe to promote Port facilities and initiatives.

Thanks. Melissa?

Melissa Knight: I started for the City as a student worker in 2004, and I think it was 2007 when I was hired full time as a Clerk Typist. Then I made my way to Sr. Admin Clerk, and then in 2017 I transferred to the Marketing Division as a Management Aide.

I started in the secretary position in the Real Estate Division for the Port. I just liked the whole aspect of helping everybody. Then I learned about the terminals, and then marketing. When they had an opening in Marketing it was an easy transition for me, and it was a promotion as well. I started working in Marketing a couple years ago.

My role here is collecting, distributing, and posting all the information into one area that’s easily accessible for everybody. That’s my contribution to help manage the supply chain. Data is collected from the Port Optimizer and is also provided by marine terminal staff. It’s a much appreciated group effort for everyone involved to get the daily information out.

And you’re working from home?

Melissa: Yes, working from home strictly. Pretty much everyone is. During the pandemic I had my first child as well.

Congratulations!

Melissa: Thank you. It’s been a really interesting couple of months.

Data Is Key

What’s been the Cargo Marketing involvement as it relates to the easing of the supply chain?

Eric: If you go back to 2014 and 2015, we had supply chain disruption issues as well. The lack of advanced cargo visibility was a big hindrance in ensuring cargo could move through the Port efficiently. Our Executive Director, Gene Seroka, wanted to change that and embarked on a digital strategy. We contracted with a company then called GE Transportation, today called Wabtec, to develop a digital cargo visibility tool called the Port Optimizer. Essentially, it is a central depository of high level shipping line volume data as their vessels depart foreign ports on their way to the Port of Los Angeles. With Port Optimizer, we can see the volume of cargo coming towards the Port three and four weeks in advance. Early on in the pandemic, we started providing advance cargo volume data to chassis providers, railroads and other supply-chain stakeholders, essentially telling them to get their ducks in a row and make sure that they are in the best possible position to handle the volume coming their way. This digital tool has evolved since then and today offers more features compared to when it was first launched.

Many more tools are available now within Port Optimizer, notably the track and trace feature that tells any interested party of the status of one or multiple containers. The role of Marketing has changed since COVID – we are spending a good amount of time tracking and tracing containers and communicating with the marine terminals on specific containers. They of course have their own internal processes on how to manage the flow of cargo. What we are trying to do is assist small and large importers in moving their cargo through the supply chain when they’ve not been successful in doing so using the traditional lines of communication.

How important was it that the Port already had systems in place to know the surge that was coming your way?

Eric: It was critical. We are really still the only port in the nation that has what we call a digital port community system that gives you the visibility to see volume of cargo coming our way in the way that we can. Much of the data Melissa pushes out every day to the various constituents using our Website is a product of Port Optimizer. It makes data available in one place, allows one to load up a whole series of container data into Port Optimizer, and see right away which terminal their containers are at. We can then communicate with the specific terminal to help expedite that cargo. Port Optimizer also led to the development of the medical optimizer to support the activities of the Logistics Victory LA project – aimed at connecting hospitals and medical facilities with the necessary supplies of PPE during the pandemic.

We did a story on that actually.

Eric: Yes, you did. We are continuing to work with our partner Wabtec to capture PPE shipment data from purchase order in Asia all the way through the supply chain until delivery. That project is ongoing.

Large importers have their own systems as well. With Port Optimizer, importers can ingest data using APIs directly into their own operating systems.

What’s the current status of the supply chain from a data standpoint?

Eric: If I had to gauge it by the number of inquiries that we’re getting via email or via phone, today or even the during last couple of weeks compared to what it was beforehand, I would say things are improving but more work is necessary. We are continuing to fill a gap for those folks who were in most need.

Tense Time

Tell us about your life over the last eight months. Did it get really stressful?

Eric: With all of us working remotely, and not being physically in front of customers, it’s been very busy in a different way. We have a whole team here in the Marketing Division – Marketing Managers Chris Chase and Marcel van Dijk, and recently retired Assistant Director of Marketing Masa Morimoto. Our support team includes of course Melissa, Mary Saucedo, who just took a position outside the Port, as well our student professional Irlanda Ramirez. The entire team works very hard every day in making sure that we responded to the inquiries in the appropriate way. It has been very, very busy from morning until evening, sometimes even as late as nine o’clock at night. It was a busy time, but exciting in a certain way. For me, one of the greater satisfactions is helping the smallest of small importers; the folks who move one or two containers per year that were really lost in the big piles; helping the “onesie twosie” importers is very, very satisfying. Of course, we value the big importers that are moving thousands upon thousands of containers as well, but for a smaller importer it is often their entire livelihood tied up in a container.

The other satisfying part is the reaction you often get from a caller when they dial the office or cellphone and can talk to a live person! I say hat’s off to the entire team here at the Port. Customer service is definitely one of our strengths.

Melissa, how about you the last eight months, and pushing data at an unprecedented time?

Melissa: It started off stressful just trying to get everything together and presented well to all the people who needed the data. And then I was juggling the home life too at the same time, working at home. Since I was pregnant I was more at risk of getting sick, so I stayed home since the beginning of the pandemic.

Eric: We never saw Melissa pregnant.

Melissa: I know! We’re working in really special times right now.

Signs of Success

With all your hard work and technology to ease the supply crunch, what signs of success are you seeing?

Eric: The number of inquiries we are getting is down; that is a good sign. Judging by Port metrics, we are seeing success in the significant efforts made by a number of folks here at the Harbor Dept. as well as by the supply chain stakeholders. If you look at the statistics that Melissa is producing – the boxes sitting on terminal more than nine days are down. The number of boxes that are leaving the Port and how long they are sitting outside before they’re being returned empty is improving as well. We are seeing improvements in the dwell time of containers that need to be railed out to destinations across the country. We are not out of the woods yet, but the successes really are shown in the numbers.

A Good Crew

You mentioned your crew a minute ago.

Eric: They’re excellent of course. I’m very lucky. All the folks in our division are very like-minded and focused on the commercial side of the house – understanding what it takes to provide excellent customer service and go the extra mile all the time. Melissa is involved in reports that probably she’s never been involved in before. Our student professional is doing customer service-type of activities, things that a student professional ordinarily wouldn’t be involved in. Everybody is really stepping up to the plate and doing multiple tasks within the team to make sure that we perform. I can’t speak highly enough of the team that we have from Chris Chase to Marcel Van Dijk, who are facing customers directly, and all the support staff — Nora Garcia, who moved to the executive offices, and Melissa Knight and Irlanda Ramirez. The Marketing Division is an exciting division because you engage with customers on a different level, obtain an appreciation and understanding of their business, and function in the total supply chain.

Thank you both for your time on a busy day.

Eric: Thank you very much.

Melissa: Thank you.