Photos for Alive! by Don Haynes, Port of LA

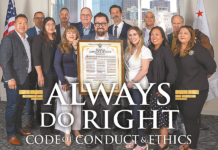

As it delivers its one millionth piece of medical gear, the Logistics Victory LA program supplies hospitals with the equipment they need during the pandemic.

Moving goods from one place to another is one of the abilities the Port of Los Angeles is really good at. In fact, the Harbor is the best in the world at doing that.

That ability has never been more important than during the coronavirus pandemic.

The Port’s newest task force, Logistics Victory LA (LoVLA), was created by Mayor Eric Garcetti to do just that – source, collect, store and distribute the millions of pieces of medical equipment and gear desperately needed by area medical centers to fight the virus and keep LA healthy.

Recently, LoVLA moved its millionth piece of gear. Alive! used the milestone to check in with the task force’s director, Port Executive Director Gene Seroka and key leader Avin Sharma, Director of Labor Relations and Workforce Development, about the project’s successes, what they learned, and the passionate crew working to keep the critically important supply chain going.

As social distancing is strictly enforced at the Port, Alive! produced this story remotely by phone, text and email.

Origins

In response to the COVID-19 pandemic, Mayor Eric Garcetti appointed Port Executive Director Gene Seroka March 31 to serve as the Chief Logistics Officer for the City while concurrently serving as chief of America’s busiest container port. With a team of 20 City employees, Seroka quickly assembled the Logistics Victory Los Angeles response effort April 7, which matches medical and non-medical suppliers of Personal Protective Equipment (PPE) with L.A. area health are providers that need PPE and other supplies to treat COVID-19 patients. LoVLA helps hospital procurement teams track and expedite these supplies across the medical supply chain that flows from overseas through the L.A. port and airport. In addition, LoVLA connects hospitals directly to suppliers and procures essential medical supplies by leveraging the purchasing capability of the City of Los Angeles.

Matching Donors With Suppliers

There remains a critical need for medical ventilators, isolation gowns, gloves, N95 masks, face shields, IV drip apparatus and other medical supplies essential for frontline healthcare workers treating those battling the coronavirus and employers with essential workers. LoVLA links providers, donors and qualified leads of these supplies with medical providers in need.

Join the Chain

Medical service providers, companies with essential workers, as well as traditional and non-traditional suppliers of PPE, and those interested in making donations are encouraged to visit LoVLA.org to submit information forms and join the LoVLA effort.

About the Logistics Victory LA Leaders

About the Logistics Victory LA Leaders

Gene Seroka

Executive Director, Port of Los Angeles, Chief Logistics Officer, City of Los Angeles

Gene Seroka is the Executive Director of the Port of Los Angeles, the busiest container port in North America. Since he was nominated by Mayor Eric Garcetti on May 27, 2014 and confirmed by the City Council on June 11, 2014, the Port of Los Angeles has experienced historic, record-breaking performances.

At the outset of the COVID-19 global health crisis, Seroka led the Port of Los Angeles’ response to the pandemic, keeping cargo flowing as an essential service to the nation. In March 2020, he was named by Mayor Garcetti as Chief Logistics Officer for the City of Los Angeles. While maintaining his duties as the Port’s Executive Director, Seroka leads the Logistics Victory Los Angeles (LoVLA) effort and has assembled a 20-member team to assist in getting critical healthcare and emergency supplies into the hands of those who need them most.

Seroka brings more than 32 years of experience in shipping, global logistics and executive management. After several key overseas positions for American President Lines (APL) Limited, he returned to the United States in 2010 to become President – Americas for the shipping line in Phoenix where he managed APL’s Liner Shipping business, including 1,000 employees, and was responsible for all commercial, port terminal, intermodal, land transportation and labor activities throughout the region.

Seroka earned an MBA and a Bachelor of science in marketing degree from the University of New Orleans.

Avin Sharma

Avin Sharma

Director of Labor Relations and Workforce Development

Avin Sharma was appointed director of this newly created division in October 2017. He joined the Port after having served in President Barack Obama’s administration. While in the Obama administration, he was the White House liaison and counselor to U.S. Secretary of Labor Tom Perez. Prior to that position, he was the economics director in the Presidential Personnel Office at the White House, and also previously served at the U.S. Dept. of Justice. Before joining the Obama administration, he was a litigation attorney in private practice.

Sharma attended the University of California, Santa Barbara, where he earned Bachelor of art degrees in business economics and political science. After completing his undergraduate studies, he attended the University of California’s Hastings College of the Law, where he earned his law degree.

A Mission to Deliver

On Aug. 4, Alive! editor John Burnes interviewed Logistics Victory LA heads Gene Seroka, Port Executive Director and Chief Logistics Officer, 6 years of City service; and Avin Sharma, Director of Workforce Development and Labor Relations, 3 years. The interview took place by phone due to social distancing.

Thank you both for talking to Alive! readers today. You both had full-time jobs with the Port before the virus pandemic hit. Is there a way to give a percentage of how much of your time you give to your regular responsibilities, and your added ones with Logistics Victory LA?

Gene Seroka: They’re two full-time jobs. Avin was one of the early folks who we put on this. We’re running as hard as we can with our official Port jobs, and then giving the same energy with LoVLA (Logistics Victory LA).

What does it mean to be the Chief Logistics Officer? What are the duties for that part of your title?

Gene Seroka: Mayor Eric Garcetti had the idea to use the talent that we have and the great assets of this City to get personal protective equipment (PPE) to our frontline hospitals and medical workers to protect them as they attempt to treat COVID-19 patients here in the Los Angeles area.

Does that involve distributing just to the City of LA, or more broadly in the area?

Gene Seroka: The mayor has said that this virus knows no boundaries, and while this is a service of the City of Los Angeles, we quickly found that there was assistance needed in the county and in the region broadly, so we have tried to help as many people as we can.

Tell me about Logistics Victory LA. What does it mean, and what does it do?

Gene Seroka: From the early days of the pandemic, we wanted to use the great LAX Airport and our seaport here in Los Angeles to speed product to market, specifically frontline hospitals and medical workers. Secondly, we wanted to leverage the long-time relationships we had with customers of the Port, those large manufacturing companies that could help us procure PPE and distribute to the hospitals. And then thirdly, we wanted to engage with manufacturers in and around Los Angeles and in the state of California who thought they could convert their facilities that were otherwise being underutilized during COVID-19 to get into PPE production. We’ve had some modest success in that area as well. With those three areas of focus, we set out to connect people who had the necessary supplies with those hospitals that were in need.

Has that changed as the program has continued? Has it evolved?

Gene Seroka: The basic premise was very solid. We’ve put together a volunteer team of about two dozen Port employees who have been following up on sales leads to procurement and sourcing, distribution, communications, and working directly with our hospitals on the products that they need. Its core tenets have held strong, and it’s all about the work now. Interestingly enough we just crossed the million-unit mark on PPE that has been distributed to more than 32 hospitals so far. It’s just extraordinary work being done by our [emergency] volunteers. In the weeks and months ahead, there’s much more to do.

Producing, Not Just Finding

Where have the successes and the challenges been in the supply chain?

Gene Seroka: The number one challenge has been finding the product. The need on behalf of the hospital workers has been much more than many could have imagined. We remember stories in the early days of companies exporting PPE [to other countries] when it was greatly needed here in the U.S. – factories could not keep up with orders, and order fulfillment was only a fraction of what was requested.

Like in the early days, we’re still seeing the same shortages, and that’s why we thought direct-to-manufacturer relationships were what we wanted to pursue.

Avin Sharma: To that end, we reached out to Honeywell back in early April. We were looking at how best to get PPE. In those early days it really was the Wild West. You had vendors, some of them with legitimate interests and others with less legitimate interests just trying to sell PPE. The article that that comes to mind is when the governor of Illinois had some staff members take a check to a McDonald’s parking lot in a frantic search to buy some PPE for the state of Illinois. There were challenges all over this country, so we talked to many of these vendors and decided, to Gene’s earlier point, to go straight to the manufacturer.

I had a contact who worked at Honeywell over a decade ago. I reached out, and he was able to facilitate some introductions with the Honeywell Corp. We jumped on the phone with Honeywell and talked to them about what our needs were and the LoVLA initiative. We worked out an arrangement with them to receive 24 million N95 masks over a 24-month period at a cost of 79 cents a mask, which is just a great price – in the early days, and frankly it hasn’t changed much, N95 masks were going for $5 or $6, or even more per mask. We were able to secure a great price, and I think that provided certainty, which was key. We needed certainty to get masks and when we would receive them. The deal provides hospitals with certainty, too, knowing when we would receive our masks and therefore when we could get them out to the hospitals, and at a cost of 79 cents. The masks are made down the 10 Freeway in Phoenix.

I imagine you also had quality certainty because there was stuff being made that wasn’t up to standards. With Honeywell, you could pretty much guarantee it was going to be the quality that the medical officials needed.

Avin Sharma: Exactly. What the medical officials needed is critical because we’re really doing two things. One is we are trying to get PPE to the hospitals. But the other thing is we’re trying to build up a stockpile here for the future. Hospitals continue to get their PPE supplies through their own medical distributors, but they’re challenged. We’re working closely with the hospitals to make sure we understand the exact items they need, and then making sure we purchase those products. We may not push some products out to the hospitals today, but we’re trying to build that inventory so if things get challenging in the fall and winter then we’ll have that inventory. We really rely on a close partnership with General Services. They’ve got an amazing team of experts who know procurement inside and out.

Got it. Are the numbers settling in now, the flow constant, or rising?

Avin Sharma: It’s growing across the supply chain. In April we had hoped that if we could get through a couple months, the case number would drop down and then the manufacturers could catch up. Obviously that never happened. Big manufacturers are trying to expand their production line. That takes time, but it’s continuing to happen. Now on the demand side from the hospitals, that’s only increased. I’m going from memory here, but I think early on you had roughly maybe 1,500 or 1,600 hospitalized patients who were COVID-positive in hospitals. Just in the last few weeks that spiked to 2,000 or 2,500. It’s now just shy of 2,000. It takes about 45 N95 masks and 45 disposable isolation gowns per COVID patient per day at a hospital. If you use that model from the Washington Post just on N95 masks alone with 2,000 hospital patients that are COVID positive, you’re looking at roughly 1.2 to 1.4 million a month. As the COVID patient cases go up we’re going to need a steady stream. As Mayor Garcetti said, the virus knows no boundaries; all our immediately neighboring counties have their challenges too.

Success Toward Victory

Talk to me about some success stories.

Gene Seroka: I mentioned earlier that we put together a team of about 24 volunteers, give or take. Two people from that team come to mind, Tim Clark and Danny Hughes, who set up an existing warehouse to manage the intake of goods that Avin and others were purchasing and get them ready for distribution out to the hospitals. In normal times, Tim and Danny are responsible for Port activity in our Construction and Maintenance division that spans about 7,500 acres and 43 miles of waterway. They had the ability to set up a true warehouse and distribution center seemingly overnight as we began to buy product. The great job by those two guys is an example of a success story.

Avin Sharma: In a similar vein is the setting up we’ve done around the vetting and procurement of products. We’ve had more than 1,100 entries to our LoVLA Website of vendors wanting to sell products. Ilene Argento, one of our colleagues here, has led the effort on vetting the companies. I’m sure you can imagine some of these companies. We all know the famous ones like Honeywell and 3M. But her research found that some companies maybe set up their license just a few days before contacting us, and we were not really sure what the product was. We vetted several hundred vendors that just didn’t pan out. Ilene created an infrastructure to evaluate and determine which vendors the City would be interested in moving forward with, and then partnering with them. That, coupled with what John Trevgoda and Melissa Yusilon are doing over at General Services on the actual procurement side. We’ve created this infrastructure and this interdepartmental symbiotic relationship to work together. At the end of the day we’ve created this new initiative to operate as a City service. We’re using public funds, and we have to work with solid vendors to purchase PPE that we know will be of suitable quality for hospitals. That’s extremely important, so I’m really proud of what they’ve set up and how we’ve been able to do that.

Unexpected Public Service

Did you ever think you’d be doing this in your careers, that you’d be handling the supply chain line during a pandemic?

Gene Seroka: The short answer is no, but I had the opportunity to live in China, and during that time the SARS epidemic broke. I got to see firsthand what a pandemic looked like. But we had not really imagined something this big, this pervasive, and simply this deadly. For the mayor to have the vision to use the apparatus and the talent in this great City of Los Angeles to in some small way help our medical frontline workers I think is just sheer genius. Then it came to us at the Port to roll up our sleeves and get after it. This is why you serve in the public sector; when you can help out your community, your fellow co-worker, or people whom you’ve never met who live in the same area you do, this is what makes you go to work every day.

Avin Sharma: No, I never thought I would be doing this. I’ve been at the Port now two and a half years, and before the Port I spent five and a half years working in the Obama administration in Washington, DC. I’ve always believed in public service and the good that that can provide to our communities and our region. In my labor role, my focus is on workforce and trying to provide quality career paths to those who need it, and I think this has just pivoted. Now our focus is on getting supplies to those who are in need most, our frontline healthcare workers and our hospitals. It’s a natural progression, and I’m just really happy to help our hospitals today.

On a Mission

Talk about the dedication of your team. Is this mission-based?

Gene Seroka: You just hit it. To a person who we’ve interacted with, and myself in particular, we have a sense of mission, and it’s people taking on double duty. There are a number of people to mention, like John and Melissa I talked about earlier at General Services, led by General Manager Tony Royster, to the folks on the ground like Connie Duran and so many others who raised their hands and asked to chip in and help, that’s really what I’ve witnessed so far. We’d never really seen anything like this before. We hadn’t done a lot of work specifically in medical procurement and distribution, but everybody read up on the material, did our research, and educated ourselves, and we learned a tremendous amount. Where we didn’t pull a lever on a purchase, we learned a little bit for the next opportunity. It’s been a story of everybody being united, trying to help, and learning as much as we can. We’re going to come out the other side not only better employees but better colleagues and people to work with.

Avin Sharma: We are building the plane as we fly it, and we had this group of volunteers really step up. This is not something we had any experience in – the medical supply chain. We don’t have any prior doctors or prior healthcare officials working here that we could quickly go to, so everyone had to learn about the masks and gloves and gowns, which manufacturers make it, and how to do procurement. In a really challenged environment, everyone is very steady and eager to learn. I could talk to you for a whole hour now about the different types of gloves that exist in the universe, and it is at the end of the day very serious stuff. You know you can’t just provide a hospital with a glove; you’ve got to provide a doctor and a nurse with a very specific type of glove that’ll keep them safe when they’re treating patients. Every single person from the Harbor Department, over at General Services, and our colleagues also in the Mayor’s Office are taking it very seriously to make sure that we get our hospital and frontline workers the proper equipment they need to do their jobs every day and night.

You must feel some sense of accomplishment, or at least I hope you would.

Avin Sharma: We’re getting some runs up on the board. We haven’t won the game yet, but we’re in the bottom of the second inning. Using that analogy I think we’re slowly getting some hits and some runs, but we’ve got a way to go to win this. We’re continuing to look to purchase other PPE and make sure we have what the hospitals need, plus the knowledge. Early on people were put on ventilators right away, now we’ve learned you’re not going to be put on a ventilator immediately; it’s not the best course, so it’s going to require some other treatment options. We’re trying our best to stay close to hospitals on their different treatments they provide so we can help them.

Gene Seroka: It comes down to the sense of mission that our volunteer team has shown. There is also our Chief of Staff, Erica Calhoun, who keeps us running day to day at this $1.5 billion department, and then David Libatique, our Deputy Executive Director of Stakeholder Engagement, a fancy way for saying he delves into everything. You’ve got folks from all different disciplines jump into trying to find product and get it to the hospitals. There’s a singular sense of purpose among the sheer versatility of the talent we have on the ground. It’s a serious and deadly pandemic, but it’s been a really great honor to be part of it.

Avin Sharma: Before I came to the Port, my last boss was (United States) Labor Secretary Tom Perez. His philosophy on putting together a team was to get the smartest people, throw them all on the bus, and then you’ll figure out what to do as you drive. I think we’ve taken that philosophy here; and we’ve put together a great group of people. People volunteered to get on this bus. We are on this journey and we’re figuring it out as we go.

Well, thank you so much, Gene and Avin, for talking to us on a very busy day.

Gene Seroka: Great, thank you!

Avin Sharma: Thanks, John.